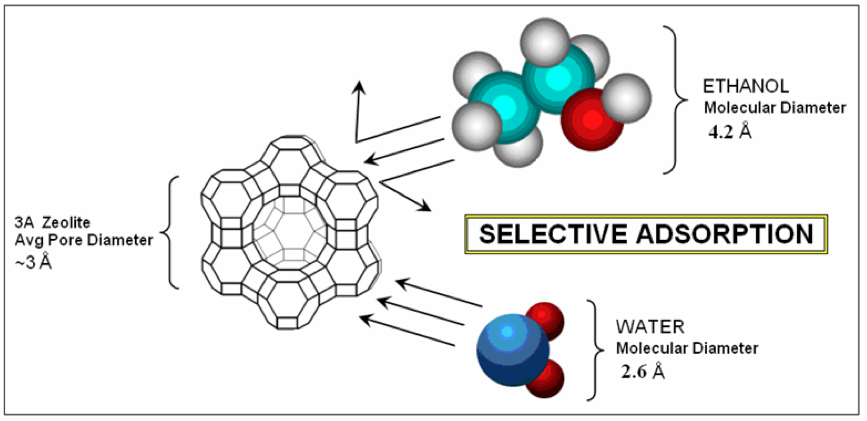

The adsorption of ethanol on 3A zeolite in the ethanol dehydration studies is usually neglected. Zeolites provide a separation based upon difference in molecular size.

Improved Adsorption Processes For Dehydration Of Alcohol Thermal Kinetics

Optimal design and operation of molecular sieve gas dehydration unitsPart 1.

. This guideline will help reader to understand about gas dehydration methods desiccant. Ethanol Dehydration Grade Molecular Sieve mSORB 3A EDG is specifically designed for the dehydration of fuel grade ethanol. Molecular Sieve Dehydrators ALCO Gas Amp Oil.

Zeochems proprietary manufacturing process provides the adsorbent superior strength and long service life avoiding costly sieve change outs and the resulting downtime. ENGINEERING DESIGN GUIDELINES GAS DEHYDRATION Rev01web. After that point mSORB EDG selectively adsorbs the water from the solution to produce anhydrous ethanol with less than 05 water.

No moving parts or additional components required to operate. Herold Contributing Writer Amsterdam The Netherlands. Water and ethanol form an azeotrope that limits how much water can be extracted by conventional distillation.

Pure ethanol 996 comes out the bottom of the dehy column ethanol-water-cyclohexane comes out the top is decanted and ethanol-water returned to rectifying column and cyclohexane back to dehydration column. Inquiry for Dehydration System. Ethanol product typically 99.

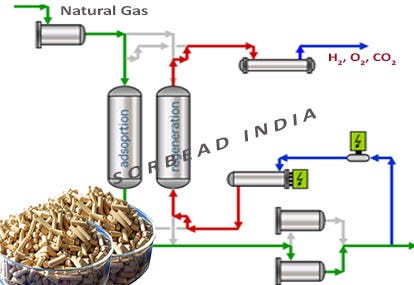

Dehydration of ethanol via adsorption on 3Å molecular sieves has recently been increasing in. Currently two- and three-bed PSA ethanol dehydration processes are common in the industry. 3Å zeolite materials are able to selectively adsorb.

Zeochems Z3-03 is the product of choice for use in the ethanol dehydration market providing excellent performance and long life. This guideline gives methods to understand basic design of gas dehydration and sizing the molecular sieve dehydrator bed. Composition of the prepared mixtures.

This guideline provides knowledge to design a gas dehydration system. The application of the molecular sieve dehydration theory with examples will make the design easier to understand for a molecular sieve dehydration unit. Removed with appropriately sized molecular sieve.

The CRCfilters EDH-2545 is a high efficiency ethanol drying system for use with 3A molecular sieve. SPECIAL REPORT Extending Mole Sieve Life Depends On. Generalized scheme of the dehydration process of ethanol 5.

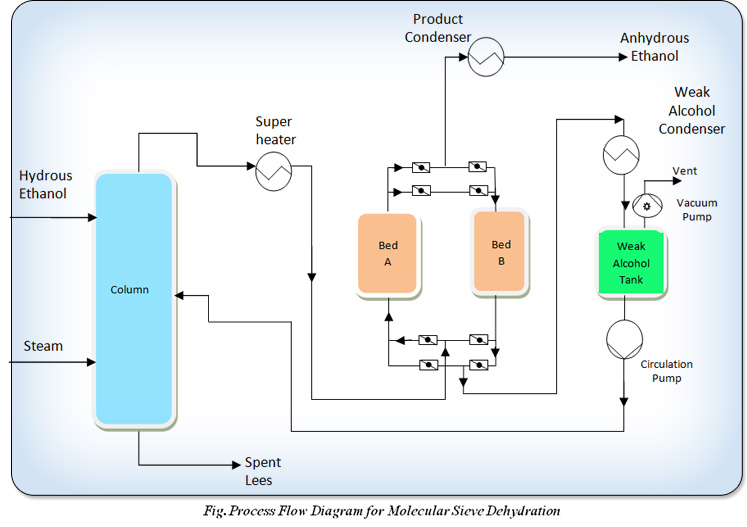

In the ethanol dehydration process the hydrated ethanol vapors are passed through the molecular sieve bed. The very precise pore size of molecular sieves enables. Overcoming Valve Failure In Molecular Sieve Service.

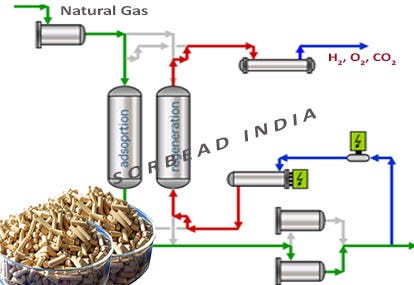

The further purification of ethanol up to 9980 is done by dehydration using pressure swing system which includes molecular sieve 3A EDG as adsorbents. Molecular sieve technology is widely used for the simultaneous removal of water and mercaptans from both gas and liquid feed streams. Commercially well-established as a separation process for dewatering the mixture of ethanol and water.

Process flow diagram of. Distillation can only remove water to approximately 5 of the total composition. This work aims to produce a molecular sieve made of zeolitic type-A by re-creating the conditions of synthesis and subsequently studying its capacity to separate an ethanol-water mixture.

Especially adsorption treating using molecular sieves. IPA Dehydration 10000galmonth 05wt to 01wt water This Liquid Phase MSDU Design passes a liquid stream of wet alcohol or solvent through a column filled with molecular sieve beads in a process known as molecular sieve dehydration. Molecular Sieve Process Optimization Featured in Biofuels International May 2015 volume 9 issue 3 Molecular sieve dehydration of ethanol uses a specialized molecular sieve to remove the water from the distillationrectification of ethanol and water.

Water molecules preferentially diffuse into the zeolite material and the larger ethanol molecules are excluded. Molecular sieves are able to concentrate ethanol to completely anhydrous state but finds ec onomical acceptance for short span of 939980 ww ethanol. Molar composition mixes Sample Na 2O Al 2O3 SiO 2.

Mokhatab Gas Processing Consultant Halifax Nova Scotia Canada. The Vogelbusch molecular sieve system allows the dehydration of ethanol past 95 purity. Please populate the following form to facilitate system design.

In lieu of this feel free to speak directly to a Wintek engineer at 973 252-8200. The 3A molecular sieve process out performs distillation at a fraction of the cost. Molecular Sieve For Ethanol Dehydration Molecular Sieve.

The process of adsorption continues until the possible water adsorption from these vapors gets completed or molecular sieve gets saturated. Our Z3-03 molecular sieve is designed for targeting only water molecules in the feed stream while minimizing the co-adsorption of ethanol and other smaller molecules. The breakthrough curves of water sorption on these adsorbents at different water contents showed that among the molecular sieves examined type 3A molecular sieves gave the best separation of the ethanolwater system and among biobased adsorbents examined natural palm stone was the best.

Using multi-pressure distillation the ethanol dehydration and water mixtures are progressively closer to the azeotropic ratio of 95545. As the vapors pass the sieve bed in the very first step water gets adsorbed by the pores of the adsorbent structure. Ethanol can only be dried to an azeotropic point of 956 purity by traditional distillation.

Precise design of PSA unit is a. Liquid Phase Molecular Sieve Dehydration Drying Ethanol with Molecular Sieves Wintek SN 160501. This dehy column simply adds say cyclohexane to break the azeotrope.

Molecular Sieves Application Guide For The Natural Gas. This molecular sieve is designed for high water content in the feed stream elevated temperatures and quick cycling all factors inherent in the ethanol drying processes. In the ethanol PSA process the water is removed with appropriately sized molecular sieve adsorbent.

Com plete dehydration by molecular sieves. PSA technology is the preferred and industrially. The Up-flow design allows for longer residency times assuring complete water remediation.

It removes water from the ethanolwater vapor mixture that exits the rectification column to gain a dehydrated product. MOLECULAR SIEVE SEQUENCING DESCRIPTION The dehydration of ethanol vapors can be accomplished by using type 3Å molecular sieve zeolites.

How To Optimize Dehydration Units Hengye

Ethanol Dehydration Grade Molecular Sieve Msorb 3a Interra Global

Fenix Process Technologies Pvt Ltd Specializes In Process Engineering Equipments Turnkey Systems

Figure 3 From Comparison Of The Main Ethanol Dehydration Technologies Through Process Simulation Semantic Scholar

Pdf Molecular Sieve Dehydration A Major Development In The Field Of Ethanol Dehydration To Produce Fuel Ethanol

Loading Ethanol Dehydration Units Hengye

Advantages Of Molecular Sieves For Dehydrating Ethanol By Molecular Sieves Medium

0 comments

Post a Comment